С точки зрения производства и использования тракторов основной тенденцией развития тракторов является

Время выпуска:

2024-09-30

Средняя мощность продолжает расти. Будь то сельскохозяйственные или промышленные тракторы

1. The average power continues to increase. Whether for agricultural or industrial tractors, in order to improve the productivity of single machine operations, the average power continues to increase, but the growth rate has shown a decreasing trend. In North America and the Soviet Union, due to their small population and large land area, agricultural production was carried out on a large scale, mostly using large agricultural machinery and equipped with corresponding high-power tractors. In general developing countries, small and medium-sized tractors are still the mainstay, but their average power is also constantly increasing.

2. Wheeled tractors have an absolute advantage in agricultural tractors. Crawler tractors are no longer widely used in agricultural production in many countries. In the Soviet Union, Italy, and China, although some tracked tractors are still in use, their proportion is also decreasing. In industrial tractors, especially bulldozers, excavators and other models, tracked tractors still have an absolute advantage. With the increase of tractor power, four-wheel drive tractors have developed rapidly. The application of hydraulic steering devices can solve the steering difficulty problem of this type of tractor, and articulated steering can greatly reduce the steering radius, which further promotes the development of high-power four-wheel drive tractors. In order to improve the traction and adhesion performance and passability in paddy fields, the four-wheel drive variant of small and medium power wheeled tractors has also achieved rapid development in countries such as Japan.

3. The safety, ease of operation, and comfort of the working environment of tractors are increasingly being valued. Designing and manufacturing a well-designed cab and various instruments can not only improve the working conditions of drivers, ensure safety, but also increase labor productivity and work quality.

4. сериализация, универсализация и стандартизация тракторов и их компонентов являются важными мерами, облегчающие производство, использование, сокращение производственных затрат и упрощение поставок аксессуаров. Чтобы удовлетворить разнообразные потребности тракторного рынка с меньшим количеством базовых моделей, крупные тракторные компании в Европе и Америке производят одну или несколько серий продукции. В таких странах, как Советский Союз, существует общенациональная унифицированная серия моделей тракторов для руководства разработкой продукции различных производственных предприятий. Разработка базовых моделей тракторов и их соответствующих вариантов с двумя или более уровнями мощности и определенными органическими соединениями, образующими серию продуктов, может позволить компонентам между продуктами иметь наивысшую степень универсальности, тем самым увеличивая партию продукции универсальных компонентов; Или можно производить аналогичные детали на одной и той же технологической линии, собирать аналогичные компоненты и смежные марки тракторов на одной и той же сборочной линии. Это очень выгодно для полного использования производственных мощностей и снижения производственных затрат.

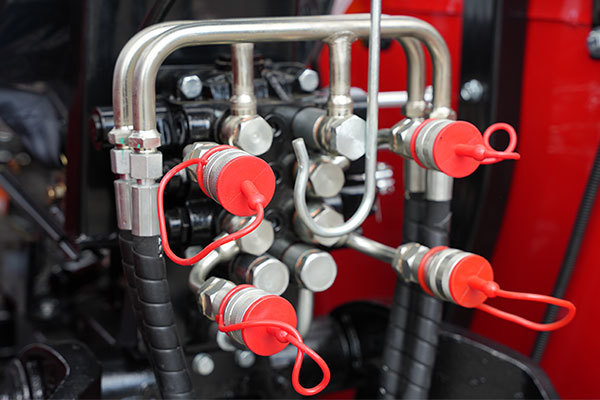

5. The application of hydraulic technology on tractors is becoming increasingly widespread. In modern tractors, especially large tractors, almost all major components are operated using hydraulic devices, such as clutches, power shifting of the gearbox, differential locks, brakes, and steering mechanisms. On some tractors, hydraulic devices are also used for seat adjustment and window opening and closing. The electronic hydraulic control suspension system has been adopted in some tractors. Due to the convenient arrangement of the control switch, the hydraulic pipeline can be shortened accordingly, and it will be more widely used in large tractors.

6. Long term exposure to random alternating loads on certain components of tractors can cause fatigue damage, affecting the reliability and lifespan of the tractor. In order to further improve product quality, large tractor companies have invested considerable funds and manpower to produce load spectra of parts under various working conditions, organize simulation tests and stress analysis, and develop electronic computer software for optimization design based on accumulated experimental data. This can not only improve product quality, but also shorten the development cycle of new products. Advanced tractor manufacturing enterprises have applied computer-aided design (CAD) methods for product design. The research and application of optimized design are also receiving increasing attention.

Связанные Новости